Full Range

Mokon's heat transfer fluid (oil) based Full Range temperature control system maximizes performance with temperatures up to 650°F (343°C). The Full Range system offers a combination heating and cooling system all in one package. A Mokon oil system, combined with an Iceman chiller, integrates the benefits and features of both products into one compact, self-support unit.

The Full Range system is ideal for jacketed vessels, mixers and reactors; multi-zone processes; installations where rapid cooling is required; and laboratory, sanitary and chemical process applications.

- Single, dual or triple zone heating configurations

- Air or water-cooled condensing chiller

- Scroll compressor for most models

- TEFC (IP54 Rating) motors that meets/exceeds NEMA Premium Efficiency levels

- Heavy-duty chiller insulated plastic reservoir

- Positive displacement process loop pump and centrifugal chiller loop pump

- Energy efficient insulated heater manifold with steel heating elements

- Cool oil reservoir design, utilizing a continuous flow heat exchanger for increased cooling efficiency which eliminates thermal shock

- Cooling heat exchanger Recirculating pump

- Process fluid high temperature and Low-pressure shut-off switches

- Automatic air purge

- Suction and discharge pressure gauges

- Y type strainer on process return

- 1/8 DIN non-proprietary microprocessor-based controller for the chilled water loop and the heat transfer fluid process loop

- Redundant heater contactor

- NEMA/Type 1 main electrical enclosure

- Main power safety door disconnect switch

- Heavy-duty ball bearing casters for portability

- Powder-coated carbon steel cabinet

- cULus 508A labeled electrical subpanel

Additional Features:

- Warranty

- 1 year on system

- 5 years on standard microprocessor controller

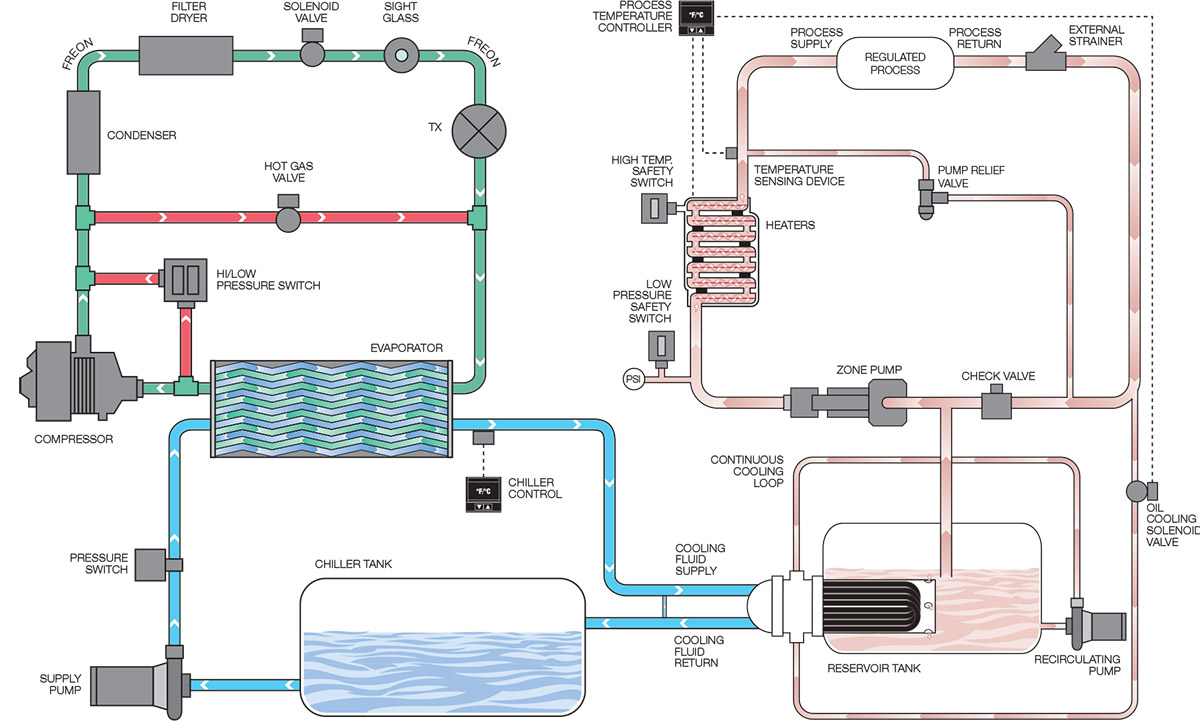

Typical Flow Schematic

- Alarms – audible and visual

- Automatic fill for chiller reservoir

- Blown fuse indication

- Controller options – remote setpoint and re-transmission, communication ports

- Emergency "crash" cooling control

- Emergency stop

- Heat exchanger flow control

- Heat Remover designs

- Heat switch

- High temperature rated hoses

- Increased cooling and heating capacities

- Low fluid level shut off

- Magnetic drive pumps

- Multi-zone sliding service tray for easy access and maintenance of pump/motor

- NEMA/Type 4, 4X, 7, and 12

- Nitrogen purge

- Other voltages, phases, frequencies

- Overhead piping kit

- Phase monitor

- Process fluid purge via air connection or switch

- Process fluid cool down/automatic shut off via time delay relay

- Remote start/stop and control panels

- Solid state contactors/relays and SCR

- Stainless steel cabinets, fluid circuits and components

- Strainers

- Tank low level indication and system shutdown

- Thermocouple with selector switch

- Thermometers

- Timers

- UL, CSA, CE and EAC certifications

- Valved process bypass via metering globe

Please consult factory for more information.

Features of Standard and Optional Controls

A variety of controls are available from Mokon to enhance the high performance of our systems. From solid state to microprocessor based, with communication capabilities to PLC type controls, Mokon can provide the type of control package right for your process.

Eurotherm 3200 Series

The Eurotherm 1/8 DIN microprocessor controller is operator friendly and easy-to-use. Standard features include a microprocessor PID controller for the highest accuracy in temperature control, a dual LCD display that shows set point and actual fluid temperature, and scrolling text messages that deliver plain language messages to let users know exactly what is happening to the process. There are optional controllers available, with high/low deviation alarm, remote set point and retransmission and serial communication. A five-year warranty comes standard with the controller.

Eurotherm 3200 Series Manual

Custom Controls

Mokon's ability to meet customers' specific requirements is seen not only in custom system designs, but also in controls. Our engineers can custom design a control package that meets your specific processing needs, from brand name controls, to direct computer/host machine interfacing. All of which can be expected with the same quality and durability that our customers expect from our complete line of temperature control systems.

| Model | Horsepower, Flow Rate & Pressure | Heating Capacity (kW) | Reservoir Volume (Gallons) | Cooling Heat Exchanger | Chiller Compressor (Hp) | Air-Cooled Condenser (BTU/Hr) @ 50°F (10°C) | Water-Cooled Condenser1 (BTU/Hr) @ 50°F (10°C) | Total Amps2 @ 460/3/60 | Approx. Dimensions (L x W x H) | Shipping Weight (Approx. lbs.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 321 | 2 Hp, 20 GPM up to 100 PSI | 12 | 38 | 7.0 sq. ft. | 3 | 34,100 | 35,300 | 28.1 | 71″ x 43″ x 52″ | 1,070 |

| 321 | 2 Hp, 20 GPM up to 100 PSI | 18 | 38 | 7.0 sq. ft. | 5 | 56,100 | 58,100 | 39.7 | 81″ x 43″ x 52″ | 1,225 |

| 321 | 2 Hp, 20 GPM up to 100 PSI | 24 | 38 | 7.0 sq. ft. | 7 1/2 | 96,872 | 100,236 | 57.2 | 81″ x 43″ x 52″ | 1,528 |

| 321 | 2 Hp, 20 GPM up to 100 PSI | 30 | 38 | 7.0 sq. ft. | 10 | 112,354 | 116,516 | 68.4 | 81″ x 43″ x 64″ | 1,692 |

| 321 | 2 Hp, 20 GPM up to 100 PSI | 36 | 38 | 7.0 sq. ft. | 10 | 112,354 | 116,516 | 76 | 81″ x 43″ x 64″ | 1,720 |

| 321 | 2 Hp, 20 GPM up to 100 PSI | 48 | 38 | 7.0 sq. ft. | 15 | 165,122 | 170,972 | 107 | 121″ x 82″ x 65″ | 2,652 |

- Based on 85°F (29°C) condensing water at 3 GPM/Ton

- To calculate FLA for other voltages, multiply the above amperages by: 2.21 for 208 volt; 2.00 for 230 volt; and 0.80 for 575 volt

Note: Process connections are 1″